Technical designation

CU-ETP, CW004A, 2.0065, EN13599, R240

Available thicknesses

- 0.5 mm

- 1.0 mm

- 1.2 mm

- 1.5 mm

- 2.0 mm

- 2.5 mm

- 3.0 mm

Alloys

Copper – ETP

Finishes

Unfinished, Vibrated, Sandblasted, Brushed and Shiny.

Main features

Easy to shape.

Perfect electrical conductor.

Antibacterial properties.

Copper (Cu) present in 99.9% purity.

Surface finish and thickness tolerance according to EN 1652.

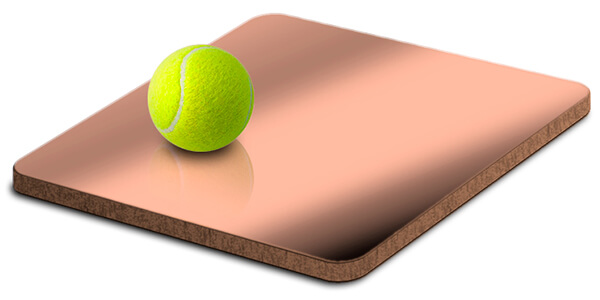

Appearance of Copper Finishes

Copper DHP - Unfinished

Copper DHP - Vibrated

Unfinished variant with vibration process, it is applied on both sides of the part with a smooth grain.

Copper DHP - SandBlasted

Unfinished variant with sandblasting process, it is applied on both sides of the part. We use glass microspheres as abrasive.

Copper DHP - Brushed Premium

Manually brushed finish with a high end aesthetic result. Finish applied in the face shown in your files. Horizontal brushed alignment. *

Copper DHP – Shiny

Premium

Manually shiny finish with a high end aesthetic result. Finish applied in the face shown in your files. *

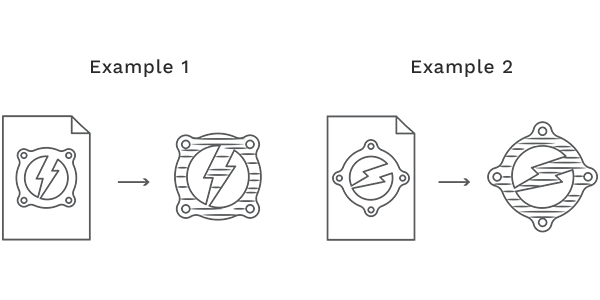

Brushed and Shiny Finish Considerations *

The brushed and shiny finish will always be present on the visible side of your file. If you select the extra aesthetic brushing, the finish will be present on both sides.

The brushing alignment will always be horizontal, according to the position of your documents.

Copper Laser Cutting Service

– Vivid color. Electric feelings. A classic.

With a magnificent electrical conductivity and unmistakable reddish appearance, copper stands out for its wide range of applications due to its also high resistance to the formation of bacteria, good ductility and its aesthetics.

In the Vibrated variant we polish with soft abrasive discs for an industrial and homogeneous finish.

For the SandBlasting finish, we operate at low pressure with glass micro spheres sand without affecting the original shape of your part, leaving the surface clean and free of imperfections.

For a more aesthetic part we recommend the Brushed or Shiny finish. If you select the extra aesthetic finish, your part will be polished after being cut on both sides.

This material can tarnish over time. For aesthetic applications we recommend to apply some protective process over the surfaces (varnish, lacquer …)

Among the most common applications of Copper, it stands out: Parts for electrical or conductive applications, electric engines parts, supplies for chemical or food industries, jewelry, signage, decorative letters, maker projects (DIY) and all kinds of applications where parts witch antibacterial behavior, excellent electrical conductivity, aesthetic appearance and easy to work with are needed.

There are many advantages of copper laser cutting, design your copper parts online.

Order Your Copper Parts Online Now

- Instant price

- Online configurator

- From 1 to 10,000 parts

- Your order ready in 72h

- Invoice instantly via email

- Optional user or company account

Instant price and online configurator. Your parts in 72h.