Finishes for your laser cut parts

In this guide, you will find detailed information about the different available finishes, their characteristics, and usage recommendations. This will help you choose the best option based on your project’s needs.

Content

-

NATURAL (unfinished) >NATURAL (unfinished) >

-

Vibrated >Vibrated >

-

Premium brushed >Premium brushed >

-

Brushed + Film Protection >Brushed + Film Protection >

-

Premium Shiny >Premium Shiny >

-

Shiny + Film Protection >Shiny + Film Protection >

-

Sandblasting >Sandblasting >

-

Oxidation and aging of materials >Oxidation and aging of materials >

NATURAL (unfinished)

The Natural finish (2B, unfinshed or no finish indicated) refers to the finish of the supply as received from the warehouse of our material suppliers.

The material may contain marks, spots, and surface scratches from the supply process or handling.

- Surface with possible marks, spots, and scratches.

- Most economical finish.

- Applications: Mechanical, industrial, prototypes, and any applications that do not require a notable aesthetic appearance.

- The back side may also include scratches or burrs. There is an option to add a deburring operation for the back side in the online configurator.

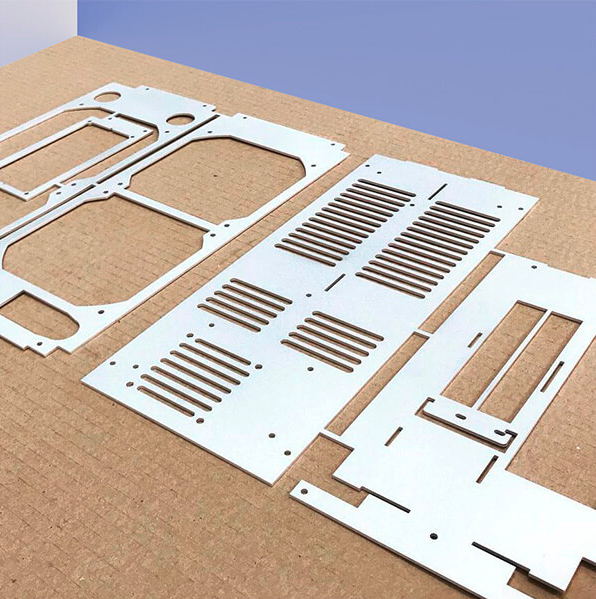

General overview of the natural finish

Detailed view of the natural finish

Carbon steel natural finish

Stainless steel natural finish

Aluminum natural finish

Brass natural finish

Copper natural finish

Aluminum natural finish without burrs

Copper natural finish without burrs

Natural iron finish without burrs

Stainless steel finish without burrs

Brass natural finish without burrs

In parts with a natural finish or without a specific treatment, as well as on back sides without finishing, discoloration may appear, especially on small contours, due to heat accumulation. This effect is normal and can only be removed through polishing. Additionally, depending on the material, thickness, and geometry, splatters or soot may form on the underside of the parts. These residues can be easily cleaned with a cloth.

For materials with a thickness of 5 mm or more, we reserve the right to remove burrs or other imperfections detected on any surface by means of localized vibration, if we consider that they significantly affect the appearance.

VIBRATED

The vibrated finish creates a smooth surface across the entire piece. The final appearance is an industrial-style finish, where the surface is covered with small, randomly directed marks. This process is applied to both sides and may contain marks from the supply process or handling.

General overview of the vibrated finish

Detailed view of the vibrated finish

Carbon steel vibrated finish

Stainless steel vibrated finish

Aluminum vibrated finish

Brass vibrated finish

Copper vibrated finish

- Industrial finish.

- Smooth and even surface. May contain marks.

- Applications: Mechanical, industrial, fitting parts, signage, art, and decoration, among others.

- The vibrated is applied to both sides.

- Surface prone to fingerprints from use and handling.

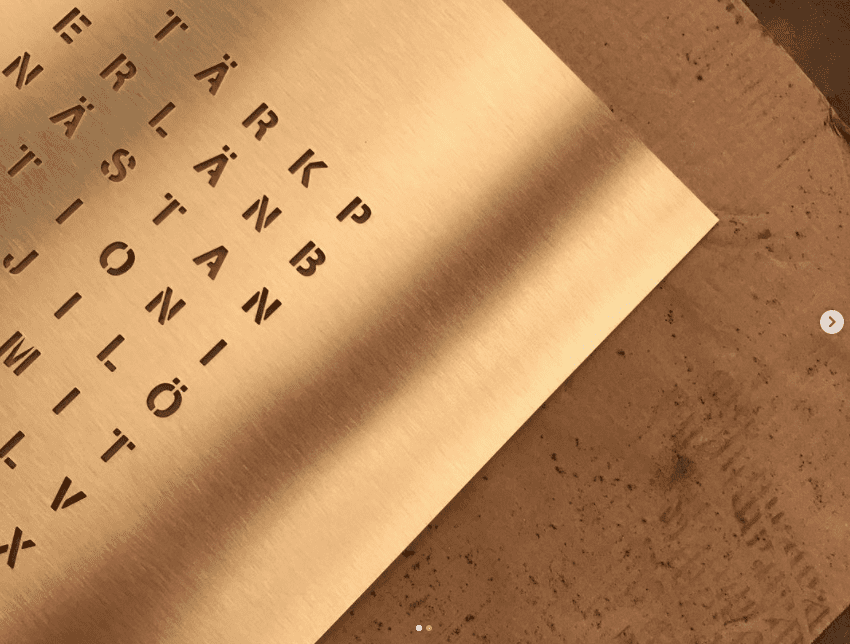

PREMIUM BRUSHED

The Premium Brushed Finish is uniform and creates an aesthetically brushed surface across the entire piece. This finish is one of the most requested for decorative applications.

The visible face will be shown in the image generated in the configurator, and the finish direction will follow a horizontal orientation according to the image. If the file is 3D and the customer requires a specific face and/or a particular finish direction, this must be clearly indicated in the text box of the part configurator. If the face or orientation is not specified, it will be defined according to the most convenient option for production.

General view of the premium brushed

Detailed view of the premium brushed

Stainless steel premium brushed

Aluminum premium brushed

Brass premium brushed

Copper premium brushed

- Highly aesthetic finish.

- Smooth and even surface.

- Applications: Decoration, art, jewelry, home, technology, and any applications where aesthetics are an added value.

- The back side will be delivered with a vibrated. There is an option to apply the premium finish on both sides of the piece in the online configurator.

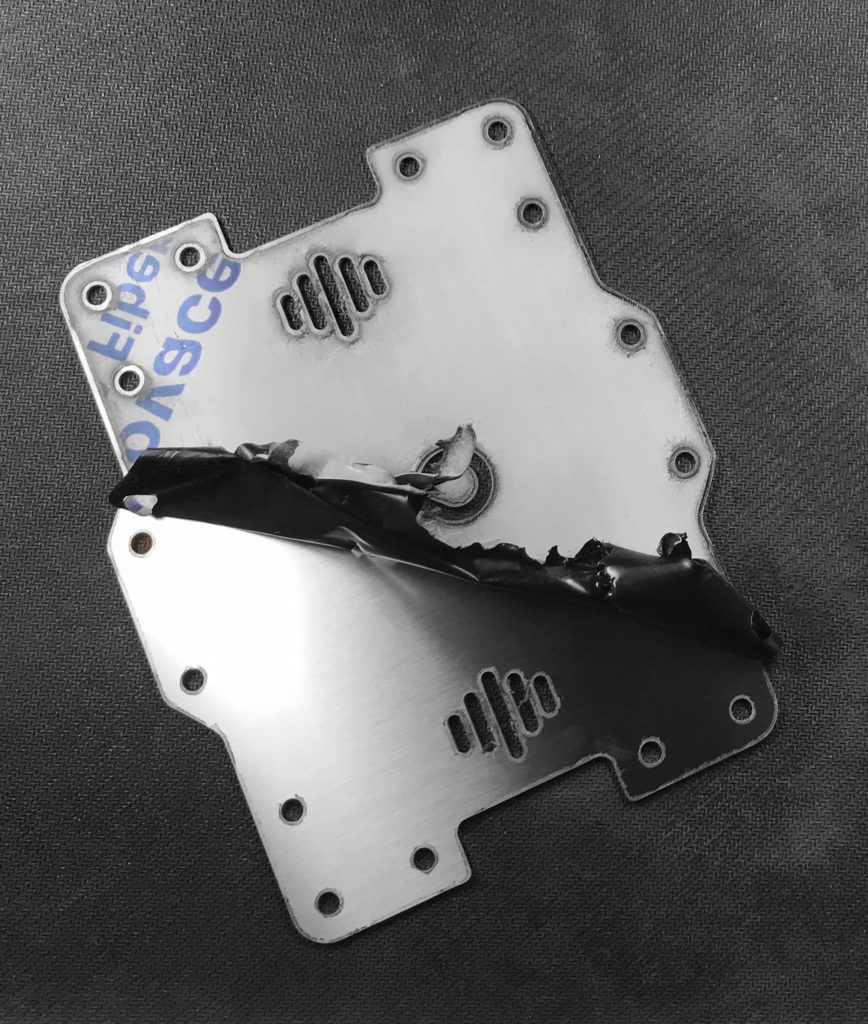

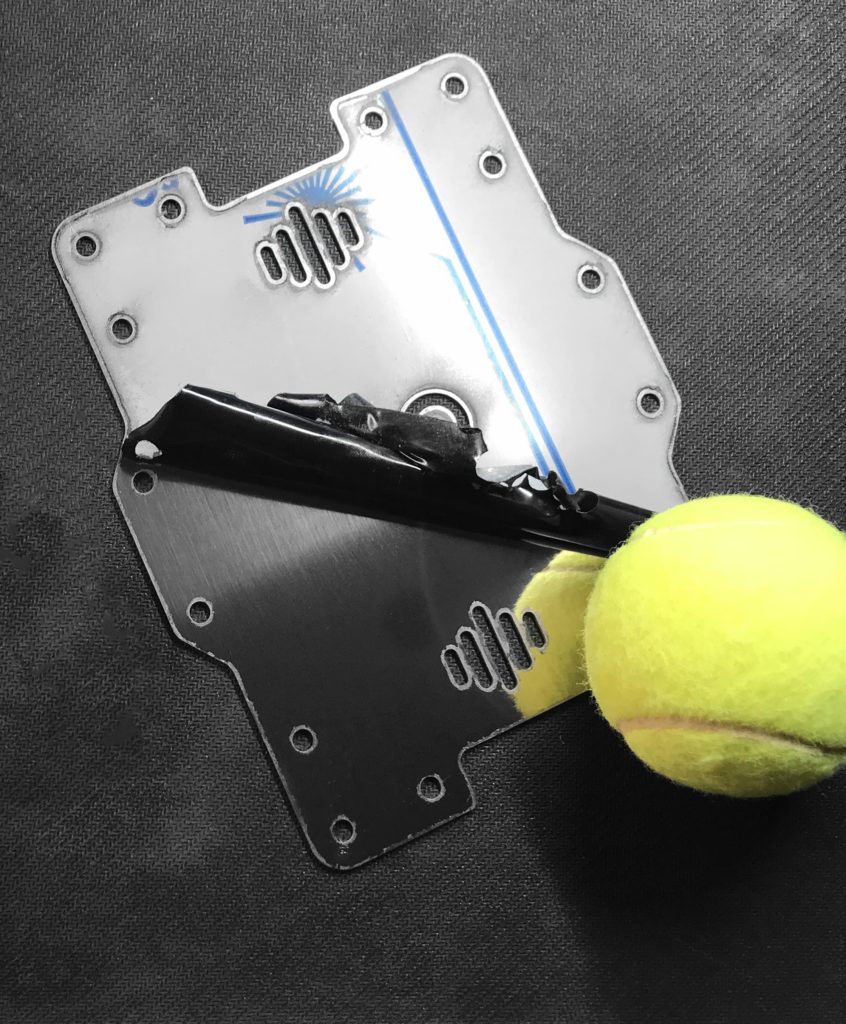

BRUSHED + Film Protector

Only available in stainless steel, this is an industrial Scotch-brushed finish (similar to the finish found on kitchen furniture or elevator interiors). It comes protected by a factory-applied PVC plastic film, which shields the surface during cutting and storage. This protective film can be easily removed manually.

The finished side (covered with plastic) will be shown in the image generated in the configurator, and the brushing direction will follow a horizontal orientation according to the image.

If the file is 3D and the customer requires a specific face and/or brushing direction, this must be clearly indicated in the text box of the part configurator. If the face or orientation is not specified, it will be defined based on the most convenient option for production.

Detailed view of the brushed finish + film protector

- Aesthetic finish.

- Smooth and even surface. All parts are delivered with the protective plastic film.

- Economical finish.

- Applications: Mechanical, industrial, signage, decoration, panels, appliances, home, and more.

- In areas with a high concentration of cuts or very small contours, the plastic film may be loosely adhered or even missing.

- The back side may include scratches or burrs, similar to the natural finish. There is an option to add a deburring operation in the online configurator.

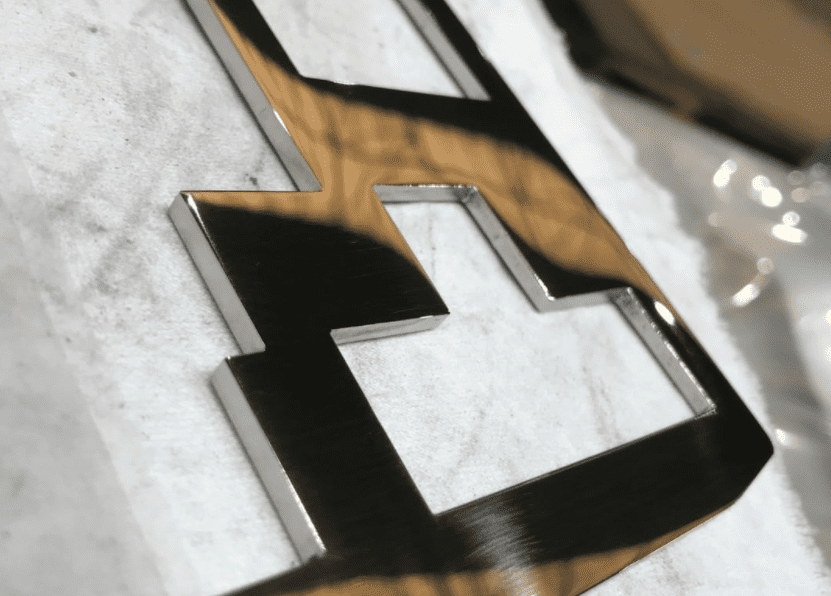

SHINY PREMIUM

The Shiny Premium is uniform and creates a highly aesthetic glossy surface across the entire piece. This finish is one of the most requested for decorative applications. The visible face will be shown in the image generated in the configurator. If the file is 3D and the customer requires a specific face for the finish, this must be clearly indicated in the text box of the part configurator. If the face is not specified, it will be defined based on the most convenient option for production.

General view of the shiny premium

Detailed view of the shiny premium

Stainless steel shiny premium

Brass shiny premium

Copper shiny premium

- Highly aesthetic finish.

- Smooth, sleek, and glossy surface, almost like a mirror.

- Applications: Decoration, art, jewelry, home, technology, automotive, motorcycles, signage, and any applications where aesthetics are an added value.

- The back side will be delivered with a vibrated. There is an option to apply the premium finish on both sides of the piece in the online configurator.

SHINY + Protective Film

Only available in stainless steel, this is an industrial shiny finish, protected by a factory-applied PVC plastic film. This plastic film safeguards the surface during cutting and storage and can be easily removed manually. The finished side (covered with plastic) will be shown in the image generated in the configurator.

If the file is 3D and the customer requires a specific face for the finish, this must be clearly indicated in the text box of the part configurator. If the face is not specified, it will be defined based on the most convenient option for production.

Detailed view of the shiny finish + film protector

- Aesthetic finish.

- Smooth and even surface. All parts are delivered with the protective plastic film.

- Economical finish.

- Applications: Industrial, signage, decoration, panels, appliances, home, and more.

- In areas with a high concentration of cuts or very small contours, the plastic film may be loosely adhered or even missing.

- The back side may include scratches or burrs, similar to the natural finish. There is an option to add a deburring operation in the online configurator.

SANDBLASTING

Sandblasting or micro-blasting is a low-pressure cleaning treatment using glass microbeads, projected onto the piece inside a sealed chamber. The resulting finish is uniform, with a matte tone that enhances the natural color of the metal and a slightly textured surface. This process is not an aesthetic finish but rather a preparatory treatment that removes impurities and leaves the surface clean and ready for painting, varnishing, or coating. The sandblasting finish is applied to both sides of the piece, including the edges.

General view of the sandblasting

Detailed view of the sandblasting

Carbon steel sandblasting

Stainless steel sandblasting

Aluminum sandblasting

Brass sandblasting finish

Copper sandblasting finish

- Clean surface with micro-texture.

- Perfect finish for subsequent painting operations.

- Applications: Mechanical, industrial, signage, decoration, jewelry, and any applications that require completely clean surfaces or subsequent coating processes.

- The sandblasting is applied to both sides, including the edges.

- Surface prone to fingerprints from use and handling.

In the micro-blasting finish, the piece is exposed to pressure and heat, which can cause slight deformations or bends, especially in softer materials and larger parts. The softer the material and the larger the piece, the higher the likelihood of deformation. At LaserBoost, we take the necessary measures to minimize this effect in designs where it is unavoidable.

Oxidation and aging of materials

Some of the materials offered by LaserBoost, such as carbon steel, copper, or brass, are susceptible to oxidation over time, exposure to the outdoors, or handling. It is important to note that LaserBoost does not perform protective treatments, such as varnishes or coatings. Therefore, if greater resistance to oxidation is required, a protective finish will need to be applied by the customer.

Carbon steel in an advanced state of oxidation.

Brass in an advanced state of oxidation.

Copper in an advanced state of oxidation.

About the User Guides, Tolerances, and Production Capabilities of the LaserBoost Service:

It is possible to manufacture parts that do not meet the capacities listed here, but the correct result of the cutting and/or bending is not guaranteed by LaserBoost if the specifications mentioned on our website are not met. If a design does not comply with any of the announced tolerances, capacities, or limitations, it can still be produced by LaserBoost at the customer’s own risk. You can validate the producibility of your design prior to placing an order by contacting our technical team at info@laserboost.com.

For more information on how to use our platform, please visit our Terms and Conditions of Service.

Credit card

| PayPal

| SEPA Transfer

| Transferencia Bancaria – Factura Proforma

Credit card

PayPal

SEPA Instant Transfer

Wire Transfer – Proforma Invoice